-40%

Handcrafted sharpener! Wasabi knife sharpener super kitchen knife sharpener

$ 52.27

- Description

- Size Guide

Description

IT IS HIGHLY RECOMMENDED TO USE CAREFULLYWHEN HANDLING SHARP BLADES

Hand-assembled Sharpening system for knives (blades, tools) VSS (V. Sharpener System), with a complete set for sharpening knives.

Sharpening knives (blades, tools) can be enjoyable

😉

This product will be appreciated by both a beginner and a professional !!!

Stylish, vintage design will look great in any kitchen or workshop.

Ease of use, premium quality and reliability are the 3 basic rules for VSS crafting.

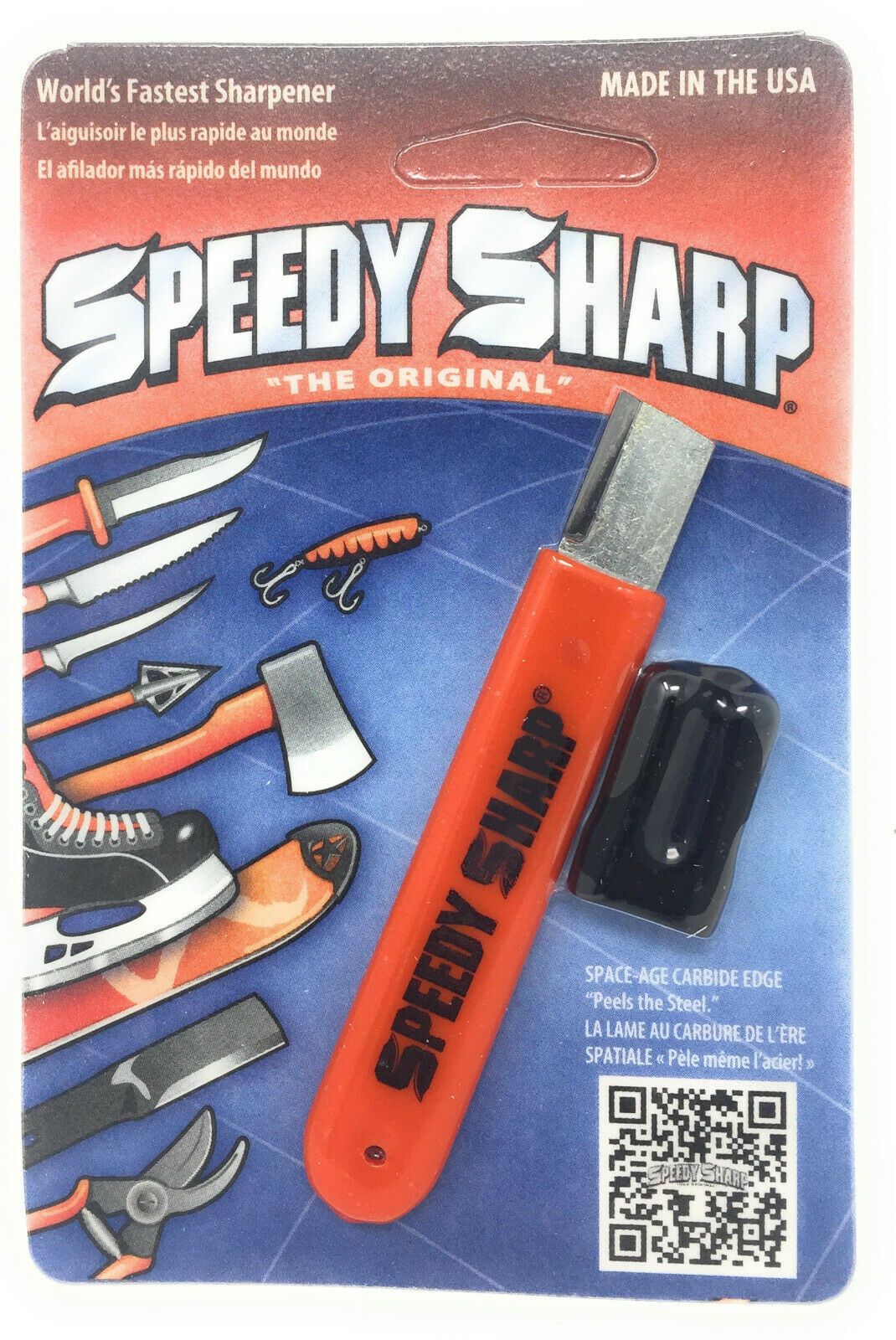

I would like to draw your attention to the fact that each VSS sharpening system will be delivered to you with the

mark of the master

as in the

second photo

. The presence of the master's mark means that the system has been personally tested by him in all parameters and corresponds to the promised highest quality.

A lot of people pay attention to the price. And the question is often asked: Why is it so expensive?

I will try to answer this question briefly..

😊

Each VSS

sharpening

system is handcrafted, which takes a lot of time to manufacture each system. We all know that the most expensive resource in our life is time!

The body is made of high quality ash wood.

Every detail is thought out, all parts of the system are professionally and reliably installed, which allows the mechanism to work easily and for a long time, all parts of the system are well processed and calibrated.

As you know - THE DEVIL IS IN THE DETAILS…

DESCRIPTION

VSS is a perfectly balanced manual machine for professional and convenient sharpening of all types of knives and some tools. A very useful tool in any kitchen, must be in every home and restaurant…

Any knife is easy to sharpen thanks to the VSS system. It uses fast attachment on powerful neodymium magnets and the ability to adjust the sharpening angle thanks to the applied marks.

Maximum degree of freedom when working thanks to integrated bearings and articulation.

INCLUDED IN THE LOT:

Sharpening system VSS

1 pc

.

Stones on blank (marking according to JIS 220, 400, 1200)

3 pcs.

Blank with leather for the finish

1 pc.

Blank form

1 pc.

SPECIFICATIONS:

VSS dimensions

10.23 x 2.76 x 6.7 inch (260 x 70 x 170 mm)

Length of the sharpening rod

19.7 inch (500 mm)

Guide diameter

0.31

inch

(

8

mm

)

Mounting type of blanks

dovetail groove, groove angle 45 degrees

The size of the blanks

6.3

x 1 x 0.12 inch (

160

x 25 x 3 mm)

The length can also be adjusted.

Type of knife (blade, tool) attachment

2 neodymium magnets

Sharpening angle

adjustable from 7 to 40 degrees

on 1 side of the blade

The maximum length of the sharpened blade

13.8 inch (350 mm)

Body material

hardwood - ash

Material of the hinge, blank holders, handle

polyacetal

Material of vertical and horizontal guide

non-magnetic stainless steel AISI 201

Stones

Water stones

.

Abrasive material - Silicon Carbide

(Carborundum 54C)

MA

RKI

NG

OF SHARPENING ANGLES (indicated on 1 side of the blade, set on the top of the hinge opposite the mark, as shown in the first photo).

Red mark

- very thin blades, chef knives, shaving blades, fillet knives, some kitchen knives (

*

approximately 10 degrees).

Yellow mark

- optimal most common angle, regular kitchen knives, folders (

*

approximately 15 degrees).

Green mark

- wide angle for cutting hard materials like bones and wood, hunting knives, bushcraft, butchers knives (

*

approximately 20 degrees).

*

The angle of sharpening may slightly differ when setting different thicknesses of blades and abrasives, therefore we will call the marks conditional, but they will completely satisfy both an ordinary user and a professional. You can also find the angle you want using a inclinometer or your smartphone by installing an angle measurement app.

IT IS HIGHLY RECOMMENDED TO USE CAREFULLY

WHEN HANDLING SHARP BLADES

HOW TO SHARP THE KNIFE (short version

😊

):

ↈ Place the knife

(

blade, tool

)

on the magnets.

ↈ Secure the square plate against the back of the knife.

ↈ Moisten the whetstone with water (or oil, whichever form you have installed).

ↈ Place the stone on the blade closer to the knife handle.

ↈ Start moving the stone along the blade.

ↈ Lift the stone and repeat the movements.

ↈ Turn the knife over and do the same.

HOW TO SHARP THE KNIFE (long version

😊

):

PREPARING THE VSS SYSTEM FOR WORK.

Fixing the device is possible in two ways:

The first one is the ledge that is located at the front, it is not only made for aesthetic appearance, but is also designed to secure the VSS to the edge of the table with a clamp.

The second - during sharpening, you can hold the VSS from the edge with your hand, as it is more convenient for someone, this allows you to feel the process. Do not think that VSS will swing from side to side and it will interfere. All reference surfaces are milled, the VSS is not light and stands well on a level surface.

INSTALLATION OF FORMS.

For the installation of the blank, holders are provided in which dovetail grooves are milled. By matching the blank and holders with each other, we get an ideal base of the blank, which constantly stands at the same point, this type of installation removes the risk that a stone or blank will fall out or skew during operation. The system for changing forms is simple and convenient: to replace them, you need to press your fingers on the movable holder, which rests against the spring and install a new one. For comfortable work, the spring force is easily adjusted by the handle itself, there is a thread cut.

INSTALLING THE KNIFE.

The knife is installed on the sharpening plate, namely on top of the magnets and is supported by a stop plate. It is unnecessary to press with this plate. They are afraid that the knife will not fall off from the magnets, their total pulling force is about 14 kg, it's like putting a large weight on it. When installing the knife, it is important to set its lead so that it is in the same plane and lies perpendicular to the axis of the sharpening bar, this largely determines the sharpening angle along the entire length of the knife.

CHOICE OF SHARPENING ANGLE.

An important element in this device is the hinge mechanism, which determines the sharpening angle. In working position, the hinge should be installed with a hole in the bottom center of the VSS. When turning with sandpaper, if the hinge is at its lowest position, the angle will be approximately 8 degrees, at the highest position, the angle will be approximately 40 degrees per side.

And since how do you set the angle exactly, there are many ways, I will voice 2 the most convenient in my opinion:

Method 1: we have a previously sharpened knife and we need to get to the previous sharpening angle: we install the blade on the sharpening table as we need, then carefully paint over the supply with a permanent marker, install the sharpening bar on top and lightly move it along the painted part, by lifting or lowering the hinge, we need to achieve that, when moving, our stone completely removes the paint equal to the width of the supply, no more and no less. If we have achieved this, then we have come to a given corner.

Method 2: More accurate method. You can precisely set the angle using the "protractor" application, which is available for free in the playmarket or apple store. We will install the smartphone on the sharpening plate from above, and set it to zero degrees, that is, the base. Next, we install the blade, put the sharpening bar with the form on top, and now the most important thing: between the holders of the forms there is a place where we put the phone, holding the phone with one hand, and with the other raising or lowering the hinge, set the desired sharpening angle, do not forget that this is an angle on one side blade. In total, it will be twice as much. You also need to take into account the angle of descents and add it.

LET'S START SHARPENING.

Let's imagine that we have a completely dull and not sharpened knife at all.

The first step is to decide on the angle and form the leads. A signal that the cutting edge is formed will be a pronounced burr on the back of the blade. In this case, the feed width must be the same on each side. The main work is done. Then everything will be much faster. The task of the next abrasive is to cover the risks of the previous one.

IT IS HIGHLY RECOMMENDED TO USE CAREFULLY

WHEN HANDLING SHARP BLADES